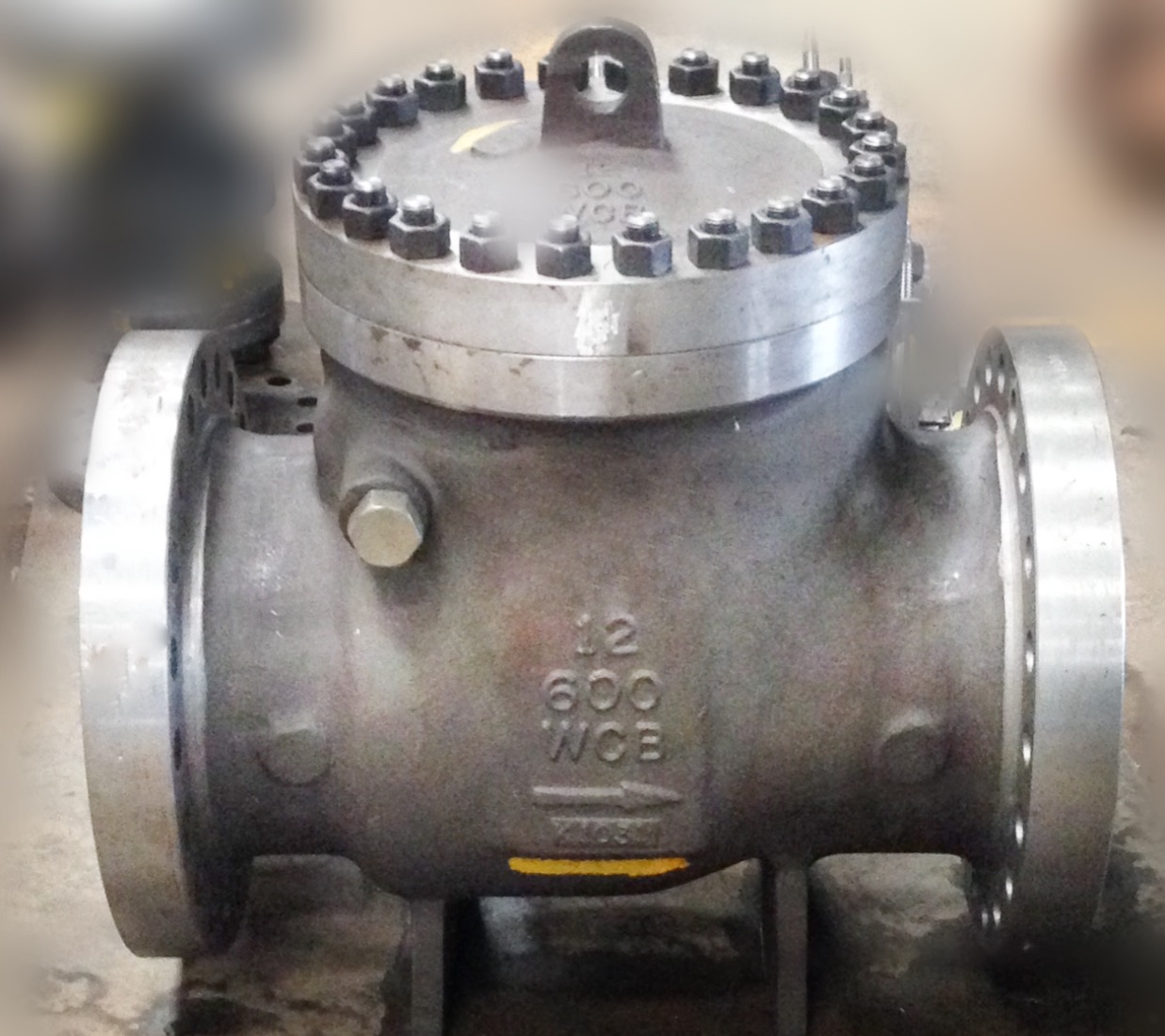

Swing Check Valve. In swing check valves, the disc is unguided when it moves to fully open position or to fully closed position. Many different disc and seat designs are available to satisfy requirements of varying applications. Soft-seated– swing check valves provide improved leak tightness compared to metal-to metal seating surfaces. Combination seats consisting of a metal seat ring with resilient insert also offer better leak tight characteristics. The seating angle, the angle between the seat and the vertical plane, may vary from 0 to 45 degrees. Vertical seats have a 0 angle. Larger seat angles reduce the disc travel, resulting in quick closing, thus minimizing the possibility of water hammer. Usually the seat angles are in the range of 5 to 7 degrees.

- Need Help? Talk to an Expert +91 93288 79000

- Send Message Us at srsvalves@gmail.com

Check Valve

Check Valves

Advantages of a Check Valve

- They are self-actuated and require no external means to actuate the valve either to open or close. They are fast acting

Disadvantages of Check Valves

- Since All Moving Parts Are Enclosed, It Is Difficult To Determine Whether The Valve Is Open Or Closed. Furthermore, The Condition Of Internal Parts Cannot Be Assessed

- Each Type Of Check Valve Has Limitations On Its Installation Configurations

- Valve Disc Can Stick In Open Position

Features

- Corrugated Steel Gasket For Class150 Valves, Spiral Wound Gasket For Class300 & Class600 Valves, And Ring Joint Gasket For Class900 & Above Valves Or As A Optional For The Class600 Valves On Customer Request

- A Hing And Hing Pin Provided And Mounted So As To Permit Full Movement Of The Disc

- Standard Renewable Seal Welded Seat With Satellite 6 While Optional Screwed In Seat

- Standard Swing Type Disc Only In Horizontal Pipe Lines Handling Liquids

Size & Rating

- CLASS 150- 2” TO 64”( DN50 TO DN1600) Equivalent EN / DIN Standards

- CLASS 300- 2” TO 60”( DN50 TO DN1500) Equivalent EN / DIN Standards

- CLASS 600- 2” TO 54”( DN50 TO DN1350) Equivalent EN / DIN Standards

- CLASS 900- 2” TO 36”( DN50 TO DN900) Equivalent EN / DIN Standards

- CLASS 1500- 2” TO 30”( DN50 TO DN750) Equivalent EN / DIN Standards

- CLASS 2500- 2” TO 24”( DN50 TO DN600) Equivalent EN / DIN Standards

Reference Standard

- Check Valves – BS 1868

- Wall Thickness & General Design ≤ Nps24- API 600 , ISO 10434.

- Wall Thickness & General Design ≥ Nps24- ASME B16.34

- Pressure Temperature Rating – ASME B16.34

- Face To Face Dimensions For Buttwelding And Flange Design- ASME B16.10

- Flange Design- ASME B16.5

- Buttewelding Design- ASME B16.25

- Materials – ASTM

- Valve Inspection And Testing – API 600, API 598, BS 6755 PART 1